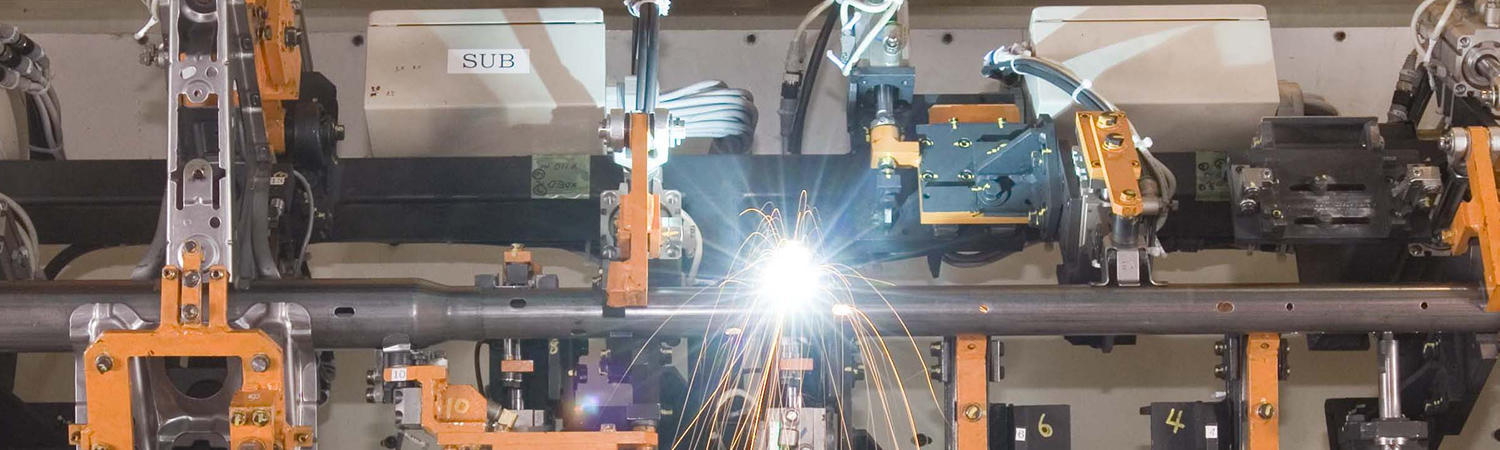

Fiber laser welding

This is a welding method with excellent beam quality that can use energy efficiently.

With fine heat input control, stable welding quality can be maintained and welding speed is excellent.

This method is used mainly for the reinforcement of instrument panels.

Compared with conventional CO2(carbon dioxide)laser welding, this welding has an energy-saving effect and contributes to the reduction of CO2 emissions.

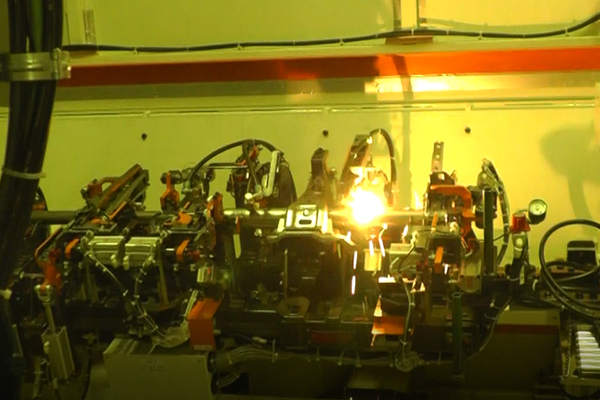

Laser beam mode control technology

This technology contributes to the improvement of join strength and stability by placing the laser output where it will contribute to

the expansion of weld width.

Stabilizing bonds has the effect of reducing spatter.

The welding method that places the required output where it is needed is original technology of Futaba and has been patented(No. 6674422).

Because this technology does not require extra output, processing with little output is possible, which contributes to energy conservation.

Comparison with previous technology

| Laser beam mode | Spatter reduction | Improvement of join strength | |

|---|---|---|---|

| Previous technology |

focus is small |

|

|

| Futaba's patented technology |

Contributes to weld stability Disperse and control light , and place required output where it is needed |

|

|