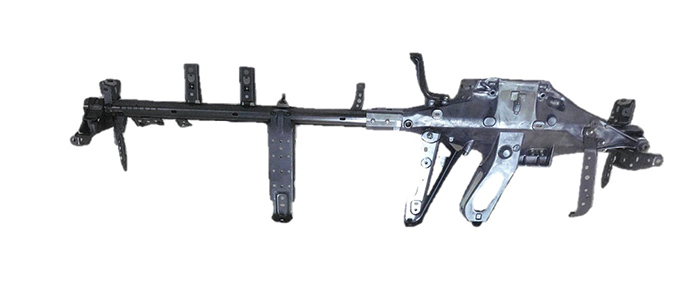

Instrument panel reinforcement using the joining of different materials, die cast aluminum and steel

Product with die cast aluminum and steel joined to achieve both steering performance and cost

In addition to conventional steel, a large piece of die cast aluminum is used on the driver's side to improve steering performance and reduce cost.

This is the first such instrument panel reinforcement adopted in Japanese vehicles which is used in new RX of Lexus.

A new global first method with this product

With this product, Futaba succeeded in joining the different base materials, steel and aluminum, using a method known as Flowform joining.*

In general, when joining two plate shaped parts, you join from one side while holding down the opposite side, but Futaba has established a new global first joining method by which two pipe-shaped parts are joined from one side only without holding down the inside of the pipe.

Because of this new method, it has become possible to join two pipe parts made of different materials without having to perform a pre-process such as drilling a hole in the pipes or attaching a nut.

This method is a world first and has been patented(No. 6606110).

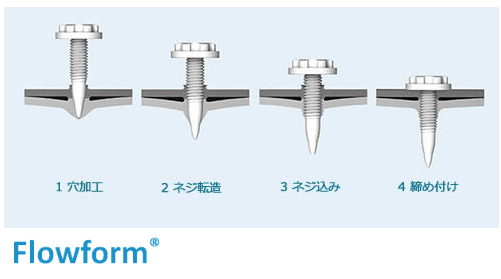

* Flowform joining

This is a joining method that enables the joining of different materials. Rotating the screw while pushing it in heats the base material by friction, the screw passes through in a semi-molten state, and it then cools and hardens to form the join.