CAE Analysis

We have realized improvements in our performance analysis technology and our ability to make proposals to customers by using CAE analysis.

We use evaluation facilities to verify probabilities based on the results of CAE analysis.

- Body

- Exhaust system

Technology related to CAE Analysis

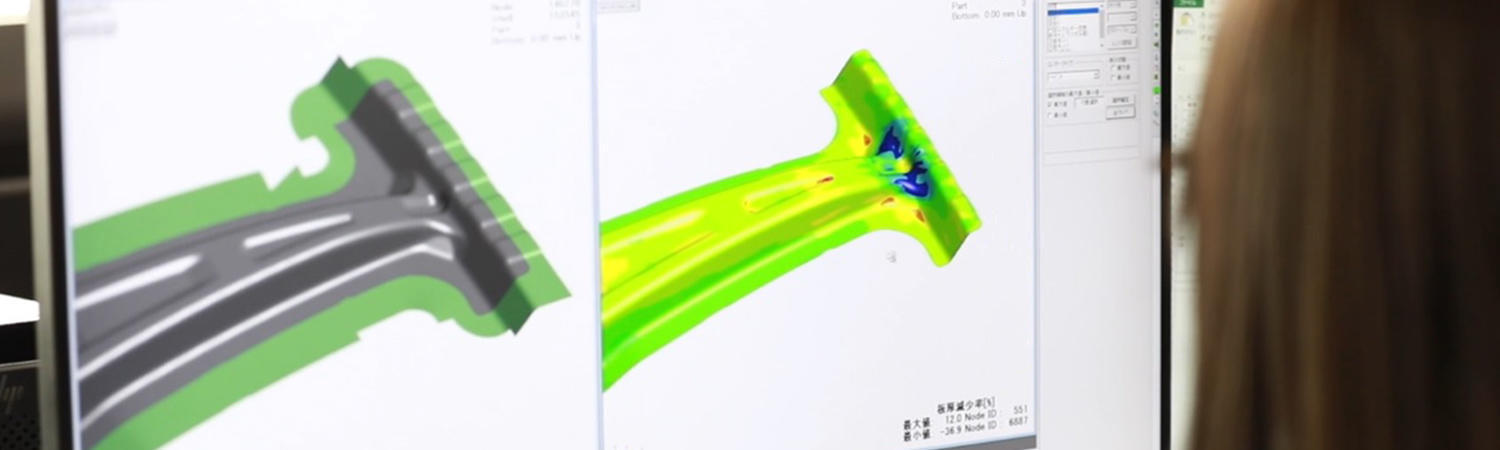

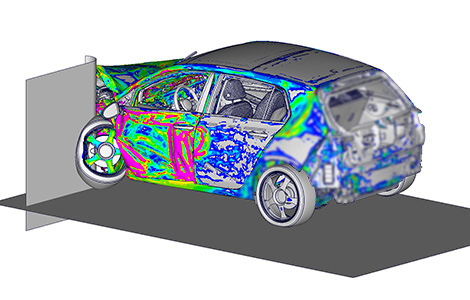

Collision analysis

-

- Starting from the production of an analytical model of an entire vehicle, we confirm whether body parts incorporated in a new structure are able to ensure the survival space of occupants at the time of a collision.

By analyzing collision phenomena and identifying places that require countermeasures, we propose efficient structures that are light and strong, and that meet customer needs.

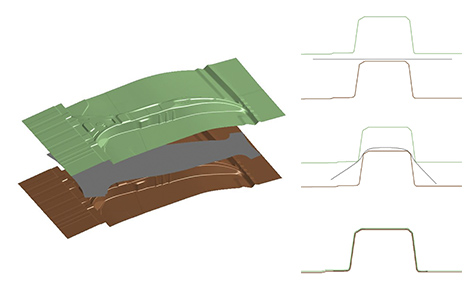

Forming analysis

-

- Because cold ultra high tensile strength materials are hard, cracks and wrinkles occur often during forming, so various devices are required in the processing process to achieve the desired shape.

As a result, we repeat forming simulations over several months to consider the production method.

Related product of collision and forming analysis

Technology related to CAE Analysis

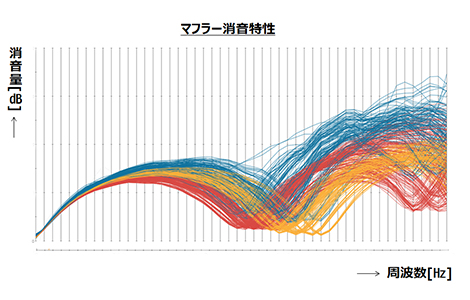

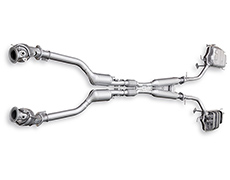

Sound analysis

-

- We analyze the timbre and silencing characteristics of exhaust systems.

We use the results for the optimization and refinement of silencing structures to predict sound pressure levels and comply with legal regulations concerning them.

-

Related product

-

Exhaust system

Exhaust system

-

-

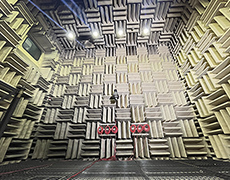

Related evaluation equipment

-

Anechoic chamber

Anechoic chamber

(exhaust pipes only) -

Anechoic chamber

Anechoic chamber

(vehicle)

-

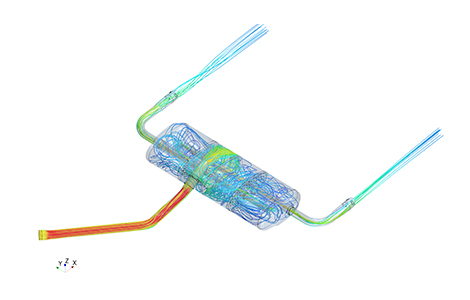

Flow analysis

-

- We find structures with little resistance by visualizing pressure loss in silencers with gas flow.

We evaluate how much resistance there is inside exhaust pipes while visualizing how gas swirls and flows within them.

-

Related product

-

Exhaust system

Exhaust system -

Exhaust manifold

Exhaust manifold

-

-

Related evaluation equipment

-

Steady flow tester

Steady flow tester

-

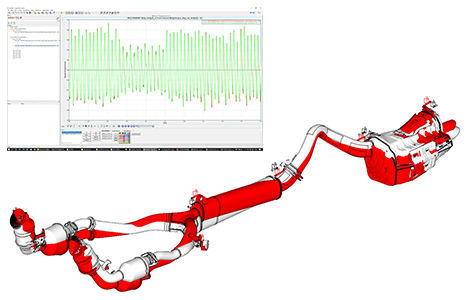

Vibration analysis

-

- We carry out vibration analysis to mitigate body input to reduce unpleasant vibrations transmitted from the exhaust pipe to the car via rubber.

-

Related product

-

Exhaust system

Exhaust system

-

-

Related evaluation equipment

-

12.5-ton vibration exciter

12.5-ton vibration exciter -

Multiaxial vibration exciter

Multiaxial vibration exciter

-

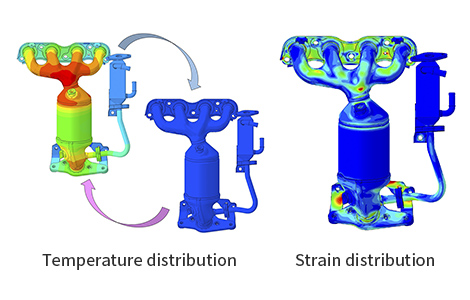

Thermal stress analysis

-

- We improve the reliability of developed products by predicting their weakest parts and lives by thermal stress analysis simulating the rise and fall of exhaust gas temperatures.

-

Related product

-

Exhaust manifold

Exhaust manifold

-

-

Related evaluation equipment

-

Engine durability test bench

Engine durability test bench -

High temperature gas generator

High temperature gas generator

-